Plastic injection molding is a smart and flexible way of making different products. It’s a method that can create precise, high-quality, and complex parts for a wide range of industries. This technology is often used to make medical devices, surgical equipment, medicine containers, and even defense products.

To help you understand what plastic injection molding is all about and how it works, here's a brief look into the process.

How Does Injection Molding Work?

Injection molding works by injecting molten plastic material into a mold cavity under high pressure. The molten plastic takes on the shape of the mold, solidifies, and is then ejected as a finished part.

This process is the preferred choice for the mass production of plastic parts in nearly every industry and offers numerous advantages. These include:

- High production efficiency: Plastic injection molding is a highly automated process. Once the injection mold tooling is set up and the process parameters are established, you can produce a large volume of parts with consistent quality. The cycle times are typically short, allowing for a high production rate. Injection mold tooling can be a single cavity or multiple cavities, further manufacturing multiple parts in each cycle.

- Versatility in design: Injection molding allows a wide range of design possibilities because the molds used in the process can be customized to create complex shapes, intricate details, and various sizes. There is also a wide selection of raw resins to choose from, including TPEs that offer a rubber-like feel to buttons, handles, and more. This creates opportunities for innovative product development and efficient integration of multiple components into a single part.

- Superior precision: Molds are very precisely machined, providing you with excellent dimensional accuracy. With the help of process engineers, the injection mold process can be made highly precise, to ensure uniform mold cavity filling, resulting in consistent part quality. Choosing an injection molder with experienced process engineers also allows you to control process parameters such as temperature, pressure, and cooling, which offers precise control over part dimensions and minimizes variations.

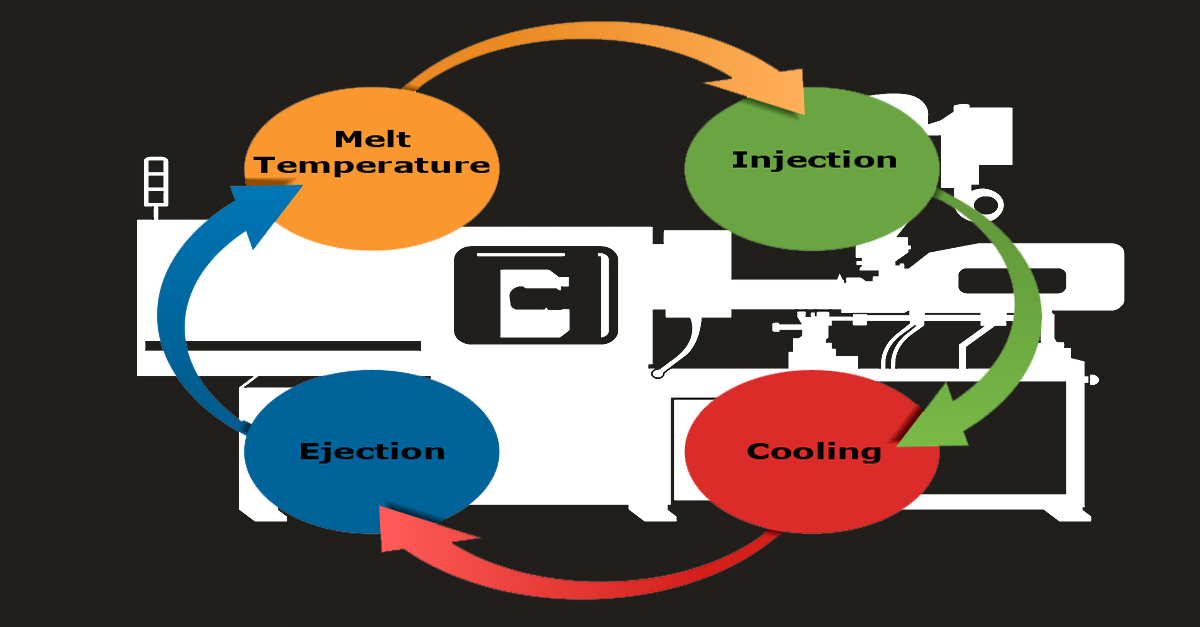

The Injection Molding Process

The plastic injection molding process has five main steps. Here's a deep dive into each of the steps of the injection molding cycle that allow for such precision, versatility, and efficiency in manufacturing.

Select the Right Thermoplastic and Mold

Selecting the right thermoplastic material and mold is a crucial step in the plastic injection molding process. Your choice of thermoplastic will depend on factors such as cost and intended application, as well as the strength, flexibility, chemical resistance, and heat stability of the material.

Here are some things to consider with each type of plastic:

- Polypropylene (PP): This plastic is known for excellent chemical resistance, impact strength, and low density. It is commonly chosen for applications that require toughness, flexibility, and fatigue resistance. It's often used in automotive parts, packaging, consumer goods, and medical devices.

- Polyethylene (PE): This plastic is known for its toughness, flexibility, and excellent electrical insulation properties. It has low moisture absorption and is resistant to chemicals, making it suitable for applications such as containers, pipes, and electrical insulation components.

- Polystyrene (PS): This plastic is known for excellent dimensional stability, clarity, and electrical insulation properties. It is lightweight and easily moldable, making it ideal for applications like packaging, disposable utensils, and electronic housings.

- Polycarbonate (PC): This plastic is known for its exceptional impact strength, heat resistance, and optical clarity. It offers excellent dimensional stability and can withstand high temperatures, making it suitable for applications requiring transparency and strength, such as lenses, safety glasses, automotive parts, and electronic housings.

The material used to make your mold is also a vital consideration. Different types of hardened steels are used when fabricating injection molds based on their durability and ability to withstand the high pressures and temperatures involved in the injection molding process. Steel molds are generally preferred for high-volume production, offering long life and precise replication of part details, but the tool steels selected are based on the raw resin material used and the annual volume of parts required.

Melt the Thermoplastic Material

Once you've decided on your plastic material, thermoplastic pellets are fed into the injection molding machine's barrel, where they undergo a carefully controlled heating and melting process. To do this, a rotating screw applies heat to the plastic material, compacts it, and pushes the melted plastic toward an injection nozzle.

The barrel's heating zones and precise temperature control allow for consistent and uniform melting throughout the material. This is vital for your final product's consistency, quality, and performance.

Injection Process

This process involves injecting the molten material into the injection unit and ensuring the proper filling and solidification of the final product. As the screw moves forward, it creates pressure and homogenizes the molten material, creating a consistent melt. The molten plastic is then forced through the nozzle and into the mold cavity by the screw driven by a hydraulic or electric motor.

Injection speed and pressure are carefully controlled to optimize the flow of the plastic material. Additionally, injection time and pressure influence even distribution and complete filling within the mold cavity. Injection pressure and speed are dictated by your plastic material's properties, the complexity of the part, and other design considerations.

Cooling Process

During the cooling stage, your molten plastic begins to solidify and takes on the shape of the mold. This stage plays a significant role in achieving dimensional accuracy, minimizing internal stresses, and ensuring product quality.

Cooling is done through either air cooling or liquid cooling. Air-cooling methods are used less frequently since they generally take more time. Cooling directly affects the overall cycle time of the injection molding process, and balancing cooling time is crucial to achieving optimal production efficiency and maintaining part quality.

Ejection and Final Steps

Once your plastic material has sufficiently cooled and solidified, the mold opens, and the ejection mechanism is engaged. Ejector pins, air blasts, or other ejection methods are employed to remove the part from the mold cavity.

After ejection, your part may need to undergo additional post-processing steps to refine its appearance, functionality, or dimensional accuracy. These steps can include:

- Trimming excess material

- Smoothing sharp edges

- Applying surface finishes such as polish, texture, or paint

The specific post-processing steps depend on the design requirements and intended application of the final product.

Choose the Right Injection Molding Partner

Plastic injection molding is a highly efficient and versatile manufacturing process, but you need the right company to take care of the plastic injection molding process for you. Crescent Industries provides an integrated, single-source solution for all your custom injection molded parts. We utilize advanced engineering to injection mold a vast range of commodity-grade resins for defense, medical, dental, and many other industries.

Contact us to inquire about your plastic injection mold needs.