Automation can improve the production of injection-molded medical and pharmaceutical parts and products, but it’s critical to approach improvements from a perspective before investing in new technology. Here, we’ll present key details of several applications where medical device contract manufacturer automated production with solutions that integrate with post-molding quality and handling systems

Coping with post-molding bottlenecks

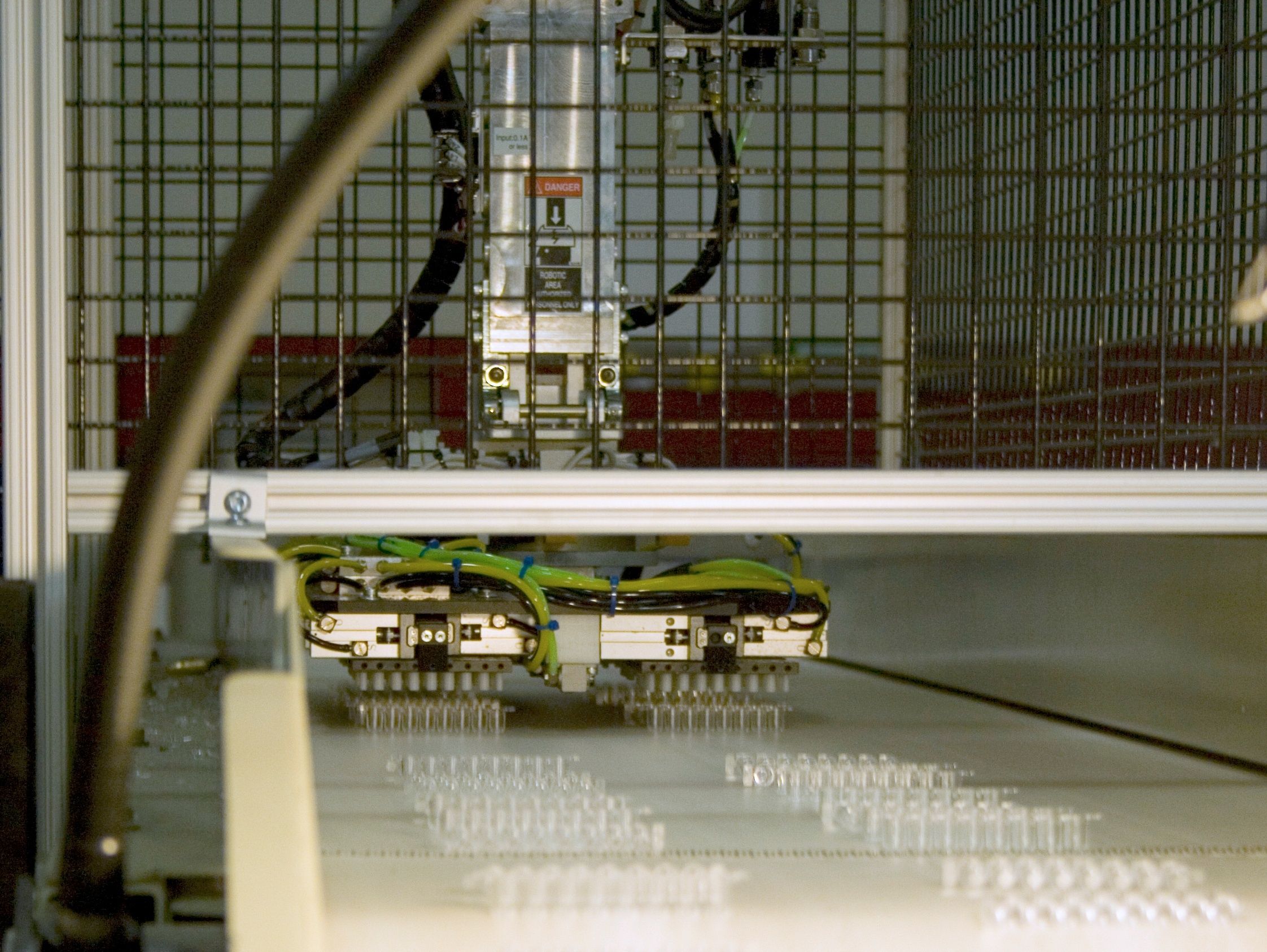

A global OEM of reagent dipsticks faced booming demand and needed new tooling and automation to produce 2.5 million parts a year. After replacing a 4-cavity hot runner with 8-cavity tool for extra capacity, demand spiked to require 4.5 million parts annually. Bottlenecks developed downstream, and automation was the solution. A fully automated work cell was designed, using 5-axis robots with custom End-of-Arm Tooling (EOAT) to remove molded parts from the press, place them on an automated turntable, and stack them for packaging. (Get a close-up tour of this work cell by clicking here.)

The results included an 18% reduction in production costs for while handling an explosive rise in capacity with improved defect-free production and reduced labor; the line didn’t require a single full-time operator. Click for more details.

For a close-up view of a work cell in action

Smaller-volume agility

It’s important to know that such technologies are aren’t just for high-volume production runs. For instance, the use of collaborative robots (cobots) is often the best way to add agility and throughput while reducing labor when more products and limited production cycle runs are needed. Learn why by reading the article, “How is Automation Used in Low to Moderate Volume Injection Molding?”

Preventing defects, reducing rejects for plastic device

A provider of 19 in vitro diagnostic plate products improved quality and throughput. Prior to the automation upgrade, parts with runners were ejected from molds and dropped onto a conveyor, causing scratches and damage that was impossible to properly inspect manually.

The automated solution integrated molding with additional steps to reduce reject rates, improve throughput and reduce labor 54%. Key elements include 3-axis collaborative robots (cobot) with custom EOATs for faster, gentler, and more accurate handling. It picks parts from the molds and performs post-mold chores – from separating and discarding runners to and orienting parts on a conveyor. The conveyor integrates machine vision inspection of 100% of the parts and rejection of defects before stacking finished trays and sending them to accumulation conveyors for packaging.

Read the case study and see a video of the system in action at this link.

A two-piece squeezer-cap container closure involving molding and, later, assembled, also benefited from similarly integrated cobots work cells, EOATs, multiple machine vision inspections, and material handling components – from pulling parts from molds to conveying them for packaging. Watch a video tour and get a detailed description in this video YouTube video.

Find more details on many of the automation components discussed here at Crescent Industries’ page, “Automation's Role in Custom Injection Molding.” Finally, if you are relatively new to the when, why and how of automation, you can gain foundational insights by reading the article, “Benefits of Automation in Medical Injection Molding.”