Plastic injection molding is the process of injecting molten plastic material into a mold to create a tool or component you need. Injection molded parts are used in medical devices, pharmaceuticals, and military applications. But, within the plastic injection molding process, there are nuances, and you may find yourself wondering about overmolding vs. insert molding and if these processes fit your project requirements.

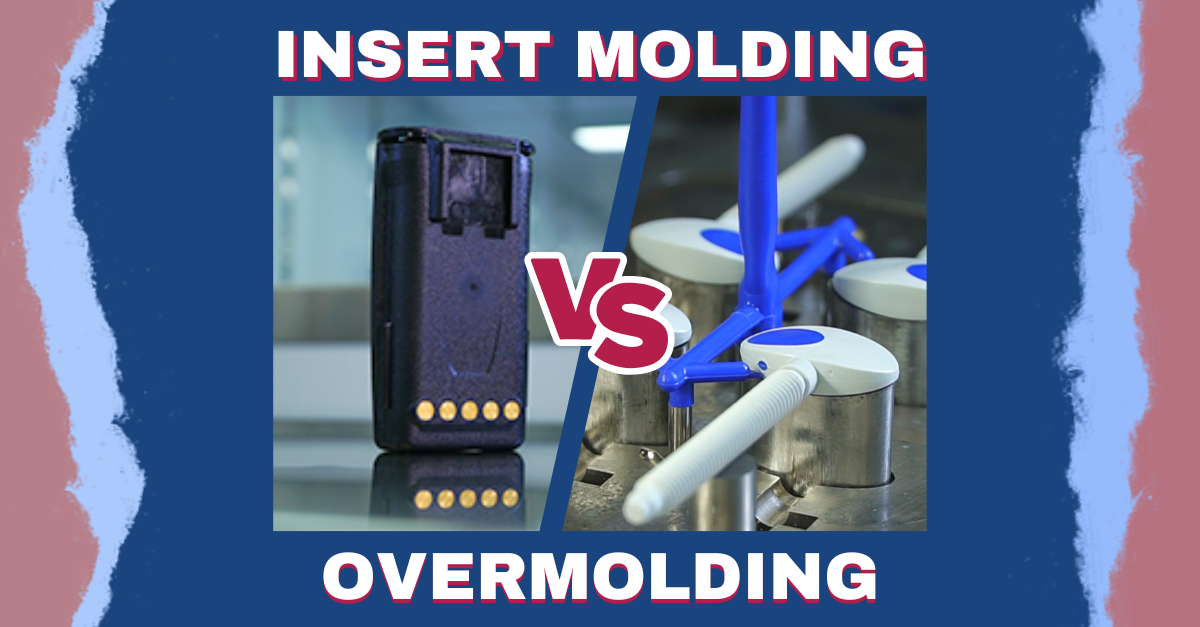

Both overmolding and insert molding are techniques used to incorporate multiple materials or components into a single molded part. While they share similarities and the terms are sometimes used interchangeably, there are distinct differences between the two processes. To find out which one of these types of injection molding is best for you, let's explore the differences and similarities.

What Is The Overmolding Process?

Overmolding is a two-step process that involves molding an additional layer of material, known as the overmold, onto a pre-formed substrate — essentially the foundation on which the overmold is laid. This allows for using multiple materials, each with unique properties, functions, or aesthetics. A great example of overmolding is your toothbrush, where a plastic handle is molded with a rubber grip placed on it.

The overmolding process allows for enhanced design flexibility and functionality.

The first step is to inject molten plastic into a cavity to form the substrate — foundation. The substrate can be made of various materials, typically a more rigid plastic.

Once the substrate is in place, the mold is opened, and the second material, the overmold, is injected into the remaining cavities. The molten plastic overmold then bonds with the substrate during the injection process, creating a strong and inseparable bond between the two materials.

What Is The Insert Molding Process?

The insert molding process involves placing typically a metal piece, known as an insert, into the mold cavity before injecting molten plastic material. Insert molding allows you to create a single integrated part that bonds the insert with the surrounding plastic material.

For the first step, a mold is prepared with a cavity accommodating the insert. This insert can be made of various metal materials and is positioned within the mold to achieve the desired functionality and strength.

After this step, molten plastic material is injected into the mold, surrounding the insert and taking shape. The plastic material adheres to the insert and creates a strong bond during this step.

Common Material Compatibility and Selection Considerations

Both overmolding and insert molding techniques can be compatible with a wide range of materials.

It's important to consider things such as design complexity, cycle time, production costs, and performance requirements when deciding between overmolding vs. insert molding. Generally speaking, projects involving metals usually use insert injection molding, as the plastic is used to make a strong handle around the metal insert. TPE is often used in overmolding to add a soft, non-slip grip to handles.

Factors Influencing The Choice Between Insert Molding vs Overmolding

The choice between insert molding and overmolding depends on several factors, including the specific requirements of the application and the desired outcome. So when you’re considering insert molding vs overmolding, consider these factors.

- Performance requirements: Performance requirements such as strength, durability, chemical resistance, and electrical properties are important to consider since different molding techniques offer different performance advantages.

- Aesthetics and ergonomics: If appearance and feel are important in the final product then overmolding can offer more options for creating visually appealing designs and incorporating soft-touch or ergonomic features.

Each application is unique, and you should consult experienced molders and engineers to ensure that you’re making the best choice for your specific product.

Unleash Injection Molding Capabilities With Crescent Industries

Crescent Industries offers both overmolding and insert molding production techniques to meet your needs. Our production designers have created high-quality injection moldings for the medical and dental industry, military and defense sectors, and many other types of molding needs for decades.

Contact us today to learn more about how we can help you meet your product manufacturing goals.