The concept behind plastic injection molding is relatively simple — to inject heated liquid plastic substrate into a mold, allow the liquid to cool to a solid, eject and repeat. This simplicity lends itself to the versatility, efficiency and availability of injection molding, but it can also lead OEMs in need of plastic injection molded components to attempt to bring those processes in-house.

Almost always, these OEMs will find that in-house injection molding leads to unforeseen cost and logistics concerns, and quickly becomes a liability to the bottom line and even the product’s quality. Instead of bringing these processes in-house, the more productive step here is outsourcing plastic injection molding to an expert in the field.

Advantages of Outsourcing Injection Molding

When you hire another company for plastic injection molding, you gain access to several advantages. These include:

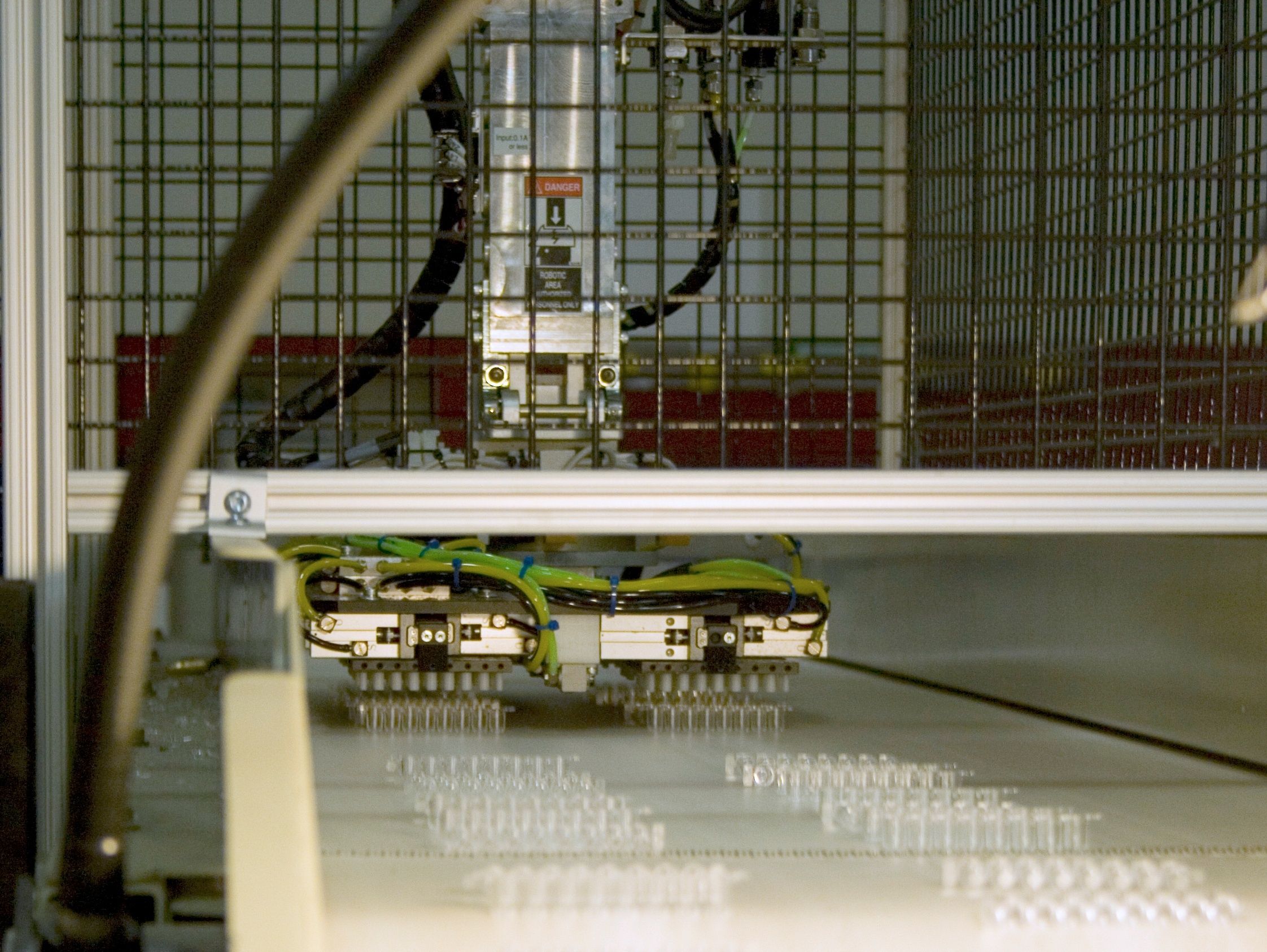

- Outsourced infrastructure: The upfront investment for injection molding machinery is sizable. Injection molding machinery is typically built to undergo millions of cycles and near-constant operation, and the cost reflects this. If an OEM only needs to operate injection molding machinery intermittently, to produce smaller quantities, the length of time to recoup that investment stretches far more than is reasonable. When you outsource injection molding, you are able to make use of someone else’s investment, freeing your capital for core competencies, innovation and other areas.

- Guaranteed expertise: With in-house injection molding, if it isn’t a core competency, you’re likely to be learning (and training) on the job — and thus paying for both of these processes. Part rejects and production errors come directly out of your bottom line, to say nothing of the time lost. With a molding partner, you are guaranteed to be working with an expert — while also freeing yourself of a training or hiring burden.

- Increased quality: With experience and expertise comes a boost in quality — whether you’re working with a molding partner for prototyping, production or both. The difference in quality from a knowledgeable molding partner is often worth the investment. Our rigorous quality standards enable us to maintain the following certifications:

- ISO 13485:2016 certified

- FDA registration

- FFL registration

- ITAR registration

In addition, we feature a decoupled molding process, which offers unsurpassed quality and repeatability. We handle each step in the fill, pack and hold process separately and apply scientific processes to help ensure that each one is carried out with a high degree of control. In the standard molding process, fill velocity and pressure affect each subsequent step, in often unpredictable ways. For more on decoupled and scientific injection molding.

This unpredictability can result in inconsistent filling, flash, inconsistent cooling and other scenarios that cause part defects, rejects and wasted material. With decoupled molding, each step is handled independently, so that, for example, pack and hold pressure can be applied independently of the filling process.

- Design and manufacturability services: Injection molding expertise is not simply a matter of knowing how to operate the machine. Although a relatively simple and versatile process, there are numerous best practices and requirements for product and mold design that can affect your cost, production efficiency and product quality. The right molding partner can assist with design and manufacturability assessments to help ensure that your pieces are produced in an efficient and effective manner. These best practices and methods include:

- Designing to optimize flow rate, with factors such as rounded corners and uniform walls

- Designing for uniform cooling time

- Incorporating gussets and ribs instead of solid walls to increase strength and use material efficiently

- Assisting with material selection for optimal flow rates according to part design

- Focus on your core competencies: As an OEM with expertise in other processes, your resources are best expended toward conducting those processes as efficiently as possible, while also driving innovation, improvement and growth. Diverting resources to another process detracts from all of those areas, negatively impacting your overall business.

One More Advantage — Cost

Many of the advantages mentioned above all feed — directly or indirectly — into one of your most important considerations: cost. Whether it’s time and money spent on training and hiring, wasted resources from rejected parts and production errors, or a negative ROI, in-house injection molding can adversely impact your bottom line in many ways. You can, however, save money with plastic injection molding outsourcing, often seeing immediate cost benefits in addition to improved efficiency and part quality.

See These Benefits With Crescent Industries

At Crescent Industries, we specialize in plastic injection molding and supporting services, including prototyping, design assistance and mold manufacturing. These key aspects of the molding process allow us to deliver full, focused services to save you money and let you focus on what you do best. To discuss your injection molding job requirements, contact Crescent Industries today.

Sources

https://crescentind.com/

https://crescentind.com/custom-injection-molding/

https://crescentind.com/quality-systems/

https://www.rodongroup.com/blog/the-advantages-of-outsourcing-plastic-injection-molding

Revision Resources

https://www.plasticsnet.com/doc/decoupled-moldingsm-0001

https://www.plasticstoday.com/injection-molding/almanac-fundamentals-decoupled-molding/4408726632942

https://crescentind.com/quality-systems/