Scientific Injection Molding Process & Benefits

In a manufacturing environment a manufacturing environment filled with predictive and data-based methods, why should your molding process stray away from what seems to be the normal buzz words over the past decade? Or why should OEM’s allow injection molders in their supply chain that don’t use more advanced molding techniques then the remaining 70% of the suppliers out there? While there are groups of people in plastics that don’t see the benefit behind always using scientific molding principles to the fullest extent of decoupled III, there’s no denying that implementing scientific molding has its benefits.

What is Scientific Injection Molding?

Scientific injection molding is a disciplined approach to using data backed decisions to setup consistent and repeatable molding processes. By creating these extremely robust molding processes, predictive quality and consistent repeatability is the outcome.

This is accomplished through 4 phases:

• Material Selection

• Part Design

• Tooling Design

• Process Development

While each of these phases is important, most people typically think solely of the 4th phase (process development) when they think of scientific injection molding. To fully implement scientific molding, it has to begin with the material selection and through part design to give the tool and production side the highest likelihood of success.

Scientific Molding vs Traditional Molding

Traditional molding principles use a single constant pressure across all of the fill/pack/hold stages, which in turn can lead to inconsistency from “shot to shot” having a process engineer chasing their tail based on the variations. With all of the variables in the injection molding process; melt flow, barrel temperature, hydraulic pressure, mold temperature, etc. utilizing a scientific molding approach curbs the fluxuations in your finished molded product. In scientific injection molding, the fill and pack/hold stages are separated and is the basis for the terminology “decoupled”.

By separating out the first two stages of the process, this limits the shot-to-shot variation and improves consistency by using the non-Newton fluid behavior of the thermoplastic. Decoupled Molding is further broken down into various forms (Decoupled I, Decoupled II and Decoupled III) and the usage of these levels is based on the injection molders equipment (eDART®) or their training level.

The injection molding process is mainly broken down into 3 separate phases:

• Fill: The cavity of the molding tool is filled between 95-99%. This partial filling of the tool establishes the foundation for consistency between shots.

• Pack/Hold: During the Pack/Hold phase the remaining volume is filled and the plastic is compressed to fully “pack” the cavity.

• Cooling/Recovery: During the final phase, Cooling/Recovery, the part is allowed to cool and becomes dimensionally stable.

The traditional molding process fills the plastic into the mold and pack it during the first stage, and then switches to a smaller pump during the hold phase, primarily to conserve energy. The holding pressure was left either at the same pressure as the first stage or, in some cases, slightly lower to minimize overpacking at the gate.

The benefits behind scientific over traditional molding at the highest level are significant for shot-to-shot consistency, predictable quality, lower scrap rates and a more robust part.

Scientific Molding Levels & Certifications

With the different molding levels within scientific injection molding comes different levels on monitoring, control and investment (financial and time) from the injection molder.

Levels

Per RJG, the different classification definitions are below:

•Decoupled I: An improved technique of molding, which can be achieved on certain types of parts, is Decoupled I. This technique was used in the 1970s when cavity pressure control was initiated. With this technique, the mold is filled at a controlled velocity until the mold is volumetrically full. At this point, the machine is transferred to a set holding pressure and melt inertia (kinetic energy and the decompression of the melt) is used to pack the mold. Filling is disconnected from packing, but the inertia of the first-stage fill is the major component of the packing process. This is a process that requires a high degree of machine repeatability and is not for the faint of heart. It is generally only used in a very limited set of specific applications.

•Decoupled II: If we are to achieve faster fill rates to take advantage of rheology, we must be able to fill quickly and consistently. The only way to do this is to fully separate the filling phase from the packing phase. If we do not separate the fast fill from the sudden stop at the end (when the cavity is volumetrically full), the melt inertia will cause a rapid buildup of pressure when the plastic hits the end of the cavity, producing flash. This is analogous to driving your car into the back wall of the garage to stop it.

A better approach is to slow down before hitting the end of the cavity, thus a decoupling the fast fill stage from the packing stage. Using Decoupled II, this is accomplished by transferring from fill into second-stage pressure when the mold is 95% to 98% full. This is analogous to driving fast on the way home from work and slowing down before parking in the garage.

•Decoupled III: The latest evolution of the Decoupled Molding technique has been to separate the process into three distinct stages: fill, pack, and hold. The first stage, fill, is achieved at one or more velocities (multiple speeds may be necessary depending on part geometry).

The packing phase is decoupled from the filling phase; however, instead of simply squeezing the plastic in under second-stage pressure, packing is done using a low-speed, controlled velocity stage until a pressure setpoint inside the mold cavity is reached. This low packing rate absorbs most of the melt inertia and allows precise levels of packing to be achieved. This is similar to driving slowly into the garage and stopping exactly when your windshield touches the tennis ball hanging from the ceiling. Hold is then used to prevent backflow of plastic out of the mold until the gate is sealed (putting the car in park and setting the brake, to extend the analogy).

Certifications and Training

One of the most well-known training companies for scientific injection molding is RJG out of Michigan, and their robust training schedule and sequences are top notch. For those looking to get a taste of the fundamentals they have specific classes in systematic molding and specific works shops for various operations, purchasing, engineering, processing and production floor personnel.

Their Master Molder® I and Master Molder® II courses are designed to put your employees to the test with 2 solid weeks of training and testing to receive the certification. For an injection molding company to consistently practice scientific molding, staying up to date with key employees’ certification is essential.

At Crescent Industries, we have employees at Master Molder® I certification and employees with Master Molder® II certifications. Crescent is committed to investing in our employee resources to continue training with the latest technology behind scientific injection molding, to ensure that our customers are getting the most value and highest quality.

How the Equipment Works

The main two areas of equipment used in scientific injection molding by RJG is the eDART® System and the in-mold sensors. These two pieces are used to communicate together along with the machine to give the injection molder a view into what’s happening in the process that they aren’t aware of.

In a traditional molding environment, processes are based on machine input. The process engineer set’s up the machine based on the inputs they enter; where it’s position, time, temperature, pressure, etc. The injection molding machine is supposed to execute on those inputs, however without secondary equipment you don’t really know whether or not those inputs where actually achieved.

The scientific molding approach instead focuses on outputs. Regardless of what your input is, by focusing on the output you can setup a more robust process based on actual data from the cycle. To see what the output is, you need the eDART® System and the in-mold sensors to communicated with the machine and tell you what’s happening in the mold during the cycle.

eDART®

The brain power behind decoupled II processing equipment is the eDART®. This essentially acts as the data collection hub and then translating that data into readable graphs, charts, outputs, etc. The equipment is connected with the machine and the sensors (if applicable). All training on the eDART® system and how to use it is covered in the Master Molder® II course at RJG. Per RJG, this course covers the below areas:

into readable graphs, charts, outputs, etc. The equipment is connected with the machine and the sensors (if applicable). All training on the eDART® system and how to use it is covered in the Master Molder® II course at RJG. Per RJG, this course covers the below areas:

Participants will learn to apply cavity pressure control strategies to accomplish Decoupled III techniques using instrumentation and data acquisition and gain a deeper understanding of the improvements Decoupled III provides for process repeatability and robustness. This course also covers use of instrumentation and how to achieve process control solutions utilizing Decoupled III processing techniques. You will learn how monitoring techniques are used to detect and contain suspect parts and how to do accurate machine and mold qualifications.

Participants will get extensive hands-on training on the RJG eDART® System. This includes system set-up, troubleshooting and data analyzer.

Course Highlights

•Cavity pressure control using Decoupled III molding techniques

•Reading and interpreting cavity pressure curves

•Matching processes on different presses using cavity pressure data

•Proper sensor location and placement

•Evaluation of molding machine performance

•Calculating process improvement

By gaining the knowledge using the eDART® System, your process engineers can now significantly enhance their implementation of scientific injection molding into the “normal” processing standards.

The cost of entry isn’t cheap to purchase, and since you need an eDART® System to run Decoupled III processes, it is a requirement to at least have one.

At Crescent Industries, we have created a cart system that has our eDART® mounted on it, along with any other equipment needed for process validation or process troubleshooting. Currently, Crescent Industries has 3 eDART® Systems on 3 separate carts. This allows us maximum mobility since the equipment does not have to be directly mounted to a machine, we can move the system from each machine as it’s needed during setup and production.

In-Mold Sensors

To gain insights into what’s happening in the mold during processing, you need to install in-mold sensors to take measurements and translate that information into the eDART®. The in-mold sensors are broken into two categories, pressure sensors and temperature sensors. As outlined by RJG, there are benefits to each type of sensor:

Cavity Pressure Sensors

Pressure data can help identify:

•Sinks

•Shorts

•Flash

•Voids

•Dimensional Variation

•Weight

•Chemical Resistance

•Warp or In-Molded Stress

Temperature Sensors

•Cooling circuit variation

•Imbalance or blockage—warp due to semi-crystalline shrinkage behavior

•Improper melt temperatures

Scientific Injection Molding Process

As with any new project, you have to first validate the tool and establish your baselines/setup to make a “good part” that is dimensionally stable as well as meeting the standards of the customer. By using a scientific approach and focusing on the outputs of the machine instead of the inputs, there is a heavier emphasis on data collection to establish baselines and a robust process of establishing the most repeatable part quality.

At Crescent Industries, we have taken our training and history in the scientific injection molding principles to apply a specific process that works best with the customers that we serve.

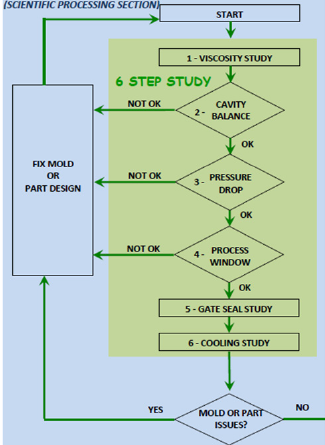

Mold Qualification

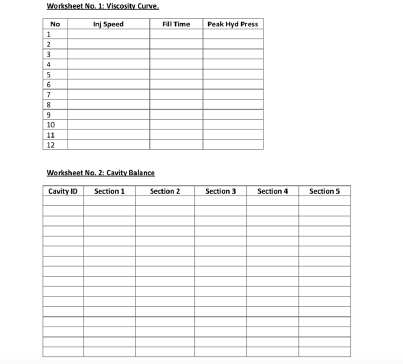

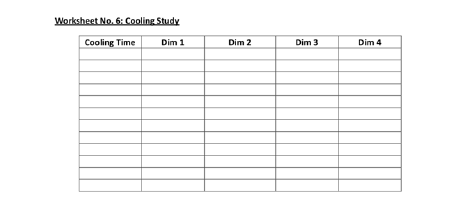

Our internal 6 step mold qualification worksheet walks us through all of the steps required to establish a robust process. This starts with the initial viscosity curve and balancing the cavities, then onto pressure drop, process window and gate seal study. Once common argument within the scientific injection molding community is whether or not you need/can always achieve a gate seal. While it is a goal to achieve one, sometimes the part design/functionality doesn’t require one. The last step of the mold qualification is the cooling study.

While we are going through our internal mold qualification process, we use specific documents to track our process and retain the values. Once these documents are saved and stored on our internal servers, we have the ability to reference back to initial trials years down the road. By working with FimmTech we have leveraged their knowledge in scientific injection molding to assist with establishing robust processes as outlined by them below:

Viscosity Curve - Output

Looking at a typical curve, one can notice that the viscosity stays fairly constant after about 60% of the injection speed. Therefore, setting the injection speed to 70% would ensure that the filling stage of the process will stay consistent. Any small natural variations will not cause large changes in viscosities resulting in shot to shot variations.

Shot to shot variations should be reduced in order to achieve repeatable quality of parts. This is especially important in case of tight tolerance parts and multi cavity molds. Optimizing the injection speed through In-mold rheology is only the first step to achieving a robust process. Later, the holding phase

and the cooling phase must also be optimized.

Cavity Balance - Output

Check the %variation between the maximum and the minimum fill for the cavities at each of the fill percentages. Record this info and perform the window study as described in the later section.

• If the parts can be packed out and the process window is large, check to see if the parts are in spec. if they are the imbalance if any is acceptable.

• If the process window is very small and you get flash on the cavity that fills first while the other is short or has sink, investigate the reason for the imbalance.

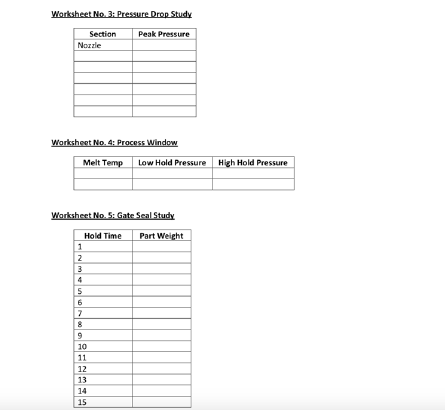

Pressure Drop - Output

The maximum pressure used in the process should never be equal to the maximum available pressure at the machine. For example, if the maximum available hydraulic pressure is 2200 psi, then the end of fill pressure should not be equal to 2200. If this is the case, it means that the screw needs more pressure to move at the set injection speed and cannot do so because of the limited pressure. Such a condition is called ‘Pressure Limited’. Typically, you should a maximum of about 90% of the maximum available pressure. Therefore, in this case, where the maximum is 2200, the end of fill pressure should not be more than 1980 psi.

In the generated graph, if you are pressure limited or more than 90% of the maximum, look for steep increases in the pressure and try to reduce these. For example, If the secondary runner section shows a steep increase, then this means it takes a lot of force to move the plastic through this section. Increasing the diameter of the runner will help in reducing this pressure.

Process Window - Output

The process window is an indicator of how much can you vary your process and still make an acceptable part. An ideal situation is you have a wide process window. If the process window is very narrow, then there is always a danger of molding parts with defects. For example, if the process window is very small, then one could get occasional short shots or occasional flash due to the natural variation in the process. A robust process is one that has a large process window and accommodates the natural variation.

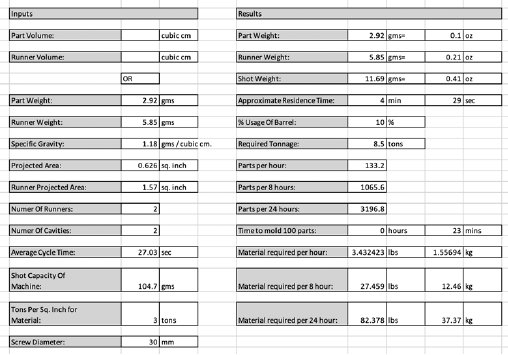

While our team is documenting the process, we are recording all of the molding calculations in a spreadsheet along with the data from the scientific injection molding equipment. This is the best way to establish a repeatable and robust process.

Conclusion

Scientific injection molding is a methodology that has been changing the molding industry for the past 20 years. As the technology continues to advance, Crescent Industries is committed to investing to ensure that our customers are getting the most value and highest quality.