The process of Assembly and/or Clean Room Assembly involves the assembling of various plastic and other components. These are used to make a sub-assembly or a complete component that succeeds as a result of utilizing techniques like Ultra sonic welding, UV bonding, air cured bonding and heat staking.

The process of Assembly and/or Clean Room Assembly involves the assembling of various plastic and other components. These are used to make a sub-assembly or a complete component that succeeds as a result of utilizing techniques like Ultra sonic welding, UV bonding, air cured bonding and heat staking.

Assembly functions can also be performed in a clean room when bio-burden and foreign particulates that can corrupt the parts and the completed assembly, which is a major concern.

What is Injection Molding with Ultra Sonic Welding?

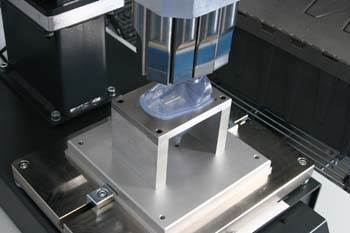

The Ultra Sonic Welding process is for joining complex plastic injection molded parts using a solid-state weld created under pressure. There are no connective bolts, nails, soldering materials or adhesives. Sonic pulses are transmitted to the part by a resonant vibrating tool called a horn, which causes two plastic materials to vibrate against each other.

Vibration will both heat and fuse these parts together. There are no glues, or solvents needed. Once the horn vibrates, it stretches and shrinks in length by a small amount. This movement is called the amplitude of the horn.

Geometrics, Materials and Fixtures

The horn must be geometrically fitted in order to match the component while simultaneously being able to vibrate efficiently. This requires superb technical expertise - and should always be as close as possible to the energy director, so that the ultrasonic waves do not lose intensity as they travel through the plastic.

The fixture is just as important as the horn geometry. This is because it must bear the brunt of all forces during the weld, while holding the components securely in place. It is also essential to select the right material for the fixture, as this ensures that the welded parts are technically and visually flawless.

Plastic products made of blends or alloys of different resin families can be joined together by ultra sonic welding. The differing materials can be welded if their melting temperature is within 30°F and their composition is compatible.

To ensure the parts are adequately joined, the injection molded components should have a suitable joint design from the beginning. There are several factors to take into consideration when designing a part to be ultrasonically welded. Some of these factors include;

- Material

- End use of product

- Cost

- Ease of injection molding and the

- Location of the joint surface relative to the horn

Ultrasonics welding is fast. Assembly rates of more than 25 parts per minute are possible within a single station. Ultrasonic welding is widely used for various component assembly applications. Some of these applications include liquid bearing vessels, IV components, hearing aids, filter assemblies, monitors and diagnostic components.

Joint Designs for Injection Molding Weld Geometries

The joint design for injection molded parts consists of adapted weld geometries with points or edges in the joining area – these are called the energy director. They focus the ultrasonic waves and define the melt initiation. Ultrasonic waves are then transmitted through the molded components and into the joining area.

The melt is formed directly between the components. It is located at the contact point of the energy director. The joint design is of critical importance for carrying out reliable processes. There are different joint designs depending on part design (wall thickness), for both the material and the requirements.

Joint Variations

Step Joint – is easy to implement in the injection mold tooling, especially when amorphous plastics are used. This joint design promotes production of visibly flawless, high-strength and air-tight welds. Other advantages include the step joint which supports self-centering of parts, and absorption of increased shear and tensile forces.

Tongue and Groove Joint – your greatest strength is usually attained by using this joint design. Gap dimensions with very small clearances create a capillary effect. This causes the generated melt to penetrate through the entire joint area. This joint design also requires thick walls, which is a fundamental recommendation.

Mash Joint – this has been used successfully for semi-crystalline plastics that combine with thin walls. With large joining distances, this joint design typically produces air-tight and high-strength welds.

Double V Joint – this is recommended for components with a wall thickness of less than 1.5 mm. Precise automatic centering of components, and the resulting defined joint positioning contribute to unusual strength after welding. It should be noted that precise injection molding, and the correct adjustment of the joint, are absolutely mandatory.

Melt Encapsulation – a well encapsulated weld joint is air-tight and flash-free. Strength is also increased when the melt is equally distributed across the joint. Amorphous plastics can be welded easily without encapsulation, due to their highly viscous melts. If injection molding reaches its limits in terms of accommodating joint designs - then some sided encapsulation is better than none.

Value, Services, Solutions

To provide customers with a single source solution, Crescent Industries offers several value-added services, either simple or complex, to complete their customers’ injection molded project. Crescent Industries will also perform custom operations as per customer request.

Learn more about Crescent Industries' contract assembly and packaging services, please click here. In order to provide a single-source manufacturing solution for your injection molded components - Crescent Industries offers several secondary operations to help complete your project.

Our experience includes simple and complex operations, depending on customer requirements. We offer design-and-build custom fixtures to aid in the assembly process. Click here to read more about Crescent Industries services and capabilities.

Citations:

Hermann Ultrasonics; article on Ultrasonic Welding Technology for Thermoplastic Materials.