How to begin transferring your injection mold tooling can be difficult. The goal is to accomplish a seamless tool transfer with minimal or uninterrupted production. The only way to accomplish this is by following a well-executed, thoroughly documented procedure. Documentation is critical, because using proven procedures is what makes it possible to have uninterrupted production.

The key to a successful tool transfer begins with planning and communication with your new injection molder by clearly defining the project goals and expectations. It is important to discuss project time lines, expectations and frequency of updates at the beginning of the process.

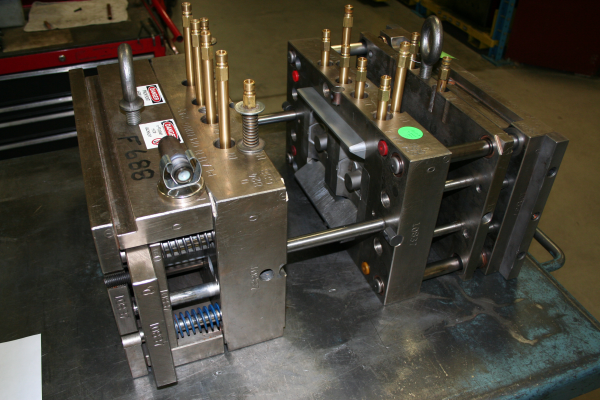

All pertinent information about the tools should be given to the new injection molder for proper evaluation and inspection of tools. The most pertinent information includes drawings, mold specifications, part information, production information, quality information - along with any required post-molding operations or auxiliary equipment that might be needed.

Make sure you and your team are discussing project time lines, expectations and frequency of project updates from very early in the tool transfer process.

Monitoring Performance and Manufacturability after the Tool Transfer

The new injection molder should perform FAIRs for you in order to evaluate and approve of its performance. Before your production runs begin, be sure to verify that all parts conform to your specifications.

They should also have the ability to provide;

- Design of experiment,

- Complete process validation

- Performance capabilities studies

- FMEA and custom control protocols based on your project requirements

To maintain manufacturability of your parts, the new molder should evaluate;

- The condition of the mold

- The resin selection

- The part geometry

- The quality specifications

~ and always properly document all items.

Determine shipping strategies like blanket orders, Kanban shipping and just-in-time delivery based on your needs. Before choosing a successor - be sure to obtain your tools and run production along with a financially stable and dependable injection molder.

Review how Crescent Industries can successfully transfer your injection molds.

This delivers an excellence and predictability for maintaining production even while tool transfers are under way.

Experience and market influence are why today's injection molders rely on stable companies that are not only financially sound - but in this case - employee owned as well. Crescent Industries delivers education, production, tools, equipment and talent. The result is high quality plastic components devices.