Developing the injection molding process is a critical step in launching your injection molded product. This step establishes the molding process parameters to ensure a stable, repeatable, and robust molding process for production that meets all quality specifications—also confirming the requirements for the proper size press and injection unit needed for your project. An experienced injection molder completes these steps with skill and expertise utilizing scientific molding principles in the molding process and Decoupled molding processes.

The critical molding process parameters are Hold Pressure (measured in PPSI – Plastic Pounds per Square Inch), Melt Temperature (°F), and Fill Time (seconds). But other elements need reviewed and optimized for a successful molding process. Therefore, the article touches only on how the critical molding process parameters are determined. Others included cavity imbalance for multi-cavity and family molds, water flow study, and more.

Clamp Force Study for Injection Molded Components

Clamp force study determines the minimum amount of clamp force (tonnage) required to properly clamp (or keep the injection mold closed) during the injection molding process. First, document the part dimensions and runner areas in square inches, then add those together to get the total product and runner area in square inches. Next, determine the material square inch measure provided by the material supplier or from existing production criteria. Finally, the total product/runner area in square inches is multiplied by the material square inches to calculate the minimum required clamp force. Of course, the calculations become complicated when products need manufacturing from a multi-cavity mold or family mold, requiring these calculations to get completed for each part.

Fill Flow in the Injection Molding Process

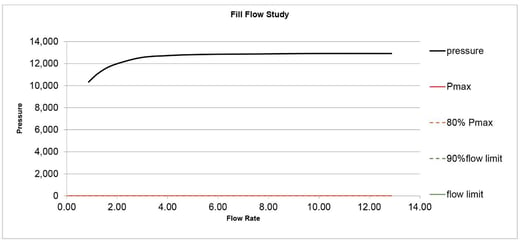

The fill flow determines the volumetric flow rate that produces quality parts on target size presses. Once you know the clamping force needed, you can record data for the machine targeted to run a particular mold. The injection molding press is set up to run a standard Decoupled II Molding process. The pack and hold pressure and time are turned off and recorded at ten different speeds, fast to slow on the fill flow. Run fast speeds product only for short shots and record transfer pressure, fill time, and part quality observation. Then do this to achieve the same fill only part size for the different speeds. Note the minimum and maximum volumetric flow rates that produce quality parts. You will also need to determine the cavity balance and machine limitation data to complete the appropriate flow rate.

Establish Melt Temperature for Injection Molding

Establish Melt Temperature for Injection Molding

To determine that the melt temperature is within the target range. The press must run for a minimum of 30 minutes to allow residence time to contribute to the melt. Then, stop the machine, retract the injection unit, purge the plastic from the barrel, and insert the temperature probe into the center of the melted resin. Record the highest melt temperature.

Hold Time During the Injection Molding Process

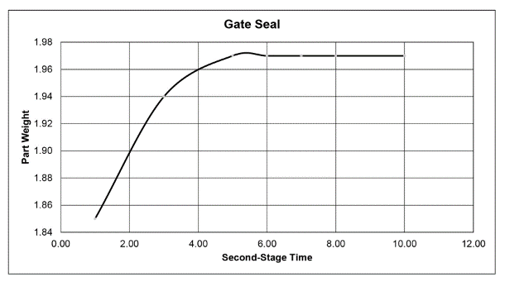

A Hold Time study determines the adequate second-stage time. Again, this starts with setting up the injection molding press to run a standard Decoupled Molding II process. Begin the process with little or no second-stage (pack and hold) time. Next, produce a short shot and record part weight for all cavities. Repeat incrementally, increasing the second-stage time. Stop once the part has stabilized, plot the data, and identify when the part weight stops rising, known as the Gate Seal Time. The optimal hold time is one second longer than the Gate Seal Time.

Establishing the parameters for a stable injection molding process allows for a quick and easy transfer to production upon accepting the DOE, OQ, PQ validation activities, and customer approval. This step to launching your injection molding project is critical, and your injection molder has a detailed data-driven method for achieving the injection molding process. For more steps to launching an injection molded project, watch the webinar now.