Welcome to the first in our series covering all aspects of injection molding: tools, considerations, and applications. In Part 1, we’ll look at single-cavity molds.

A single-cavity mold produces one component per cycle. After injecting the molten resin into the mold cavity, the liquid plastic flows through the runner system into the single cavity. The packing, holding, and cooling steps occur as they would in every molding process. The resulting part is then ejected for inspection, and the next molding cycle begins.

While single-cavity injection molding is common practice, there are some pros and cons to the technique.

Pros

- Offers a lower upfront cost for mold design and production

- May offer a shorter lead time for mold manufacture

- Cost-effective for lower-volume production runs, especially in quantities below 1000 parts

- Good for interim or temporary solutions to meet surge or cyclical demand

Cons

- Not suitable for high-volume production

- May not be able to keep up with increasing demand

- The overall cost per part is higher over the life of the mold

Next, we’ll look at specific applications where a single-cavity mold might be the best option for injection molding projects.

Single-Cavity Mold Uses for Injection Molding

Here, we will learn more about the specific circumstances under which single-cavity injection molding is likely the preferred choice for a project. A single-cavity mold is commonly used for:

- New products where demand is not yet known

- Specialty products with lower volumes

- More intricate parts or unique designs where more significant control over injection pressure and material flow would be beneficial

- Price-sensitive applications, where a low upfront cost is desirable

- Certain circumstances when the overall speed of production is not material

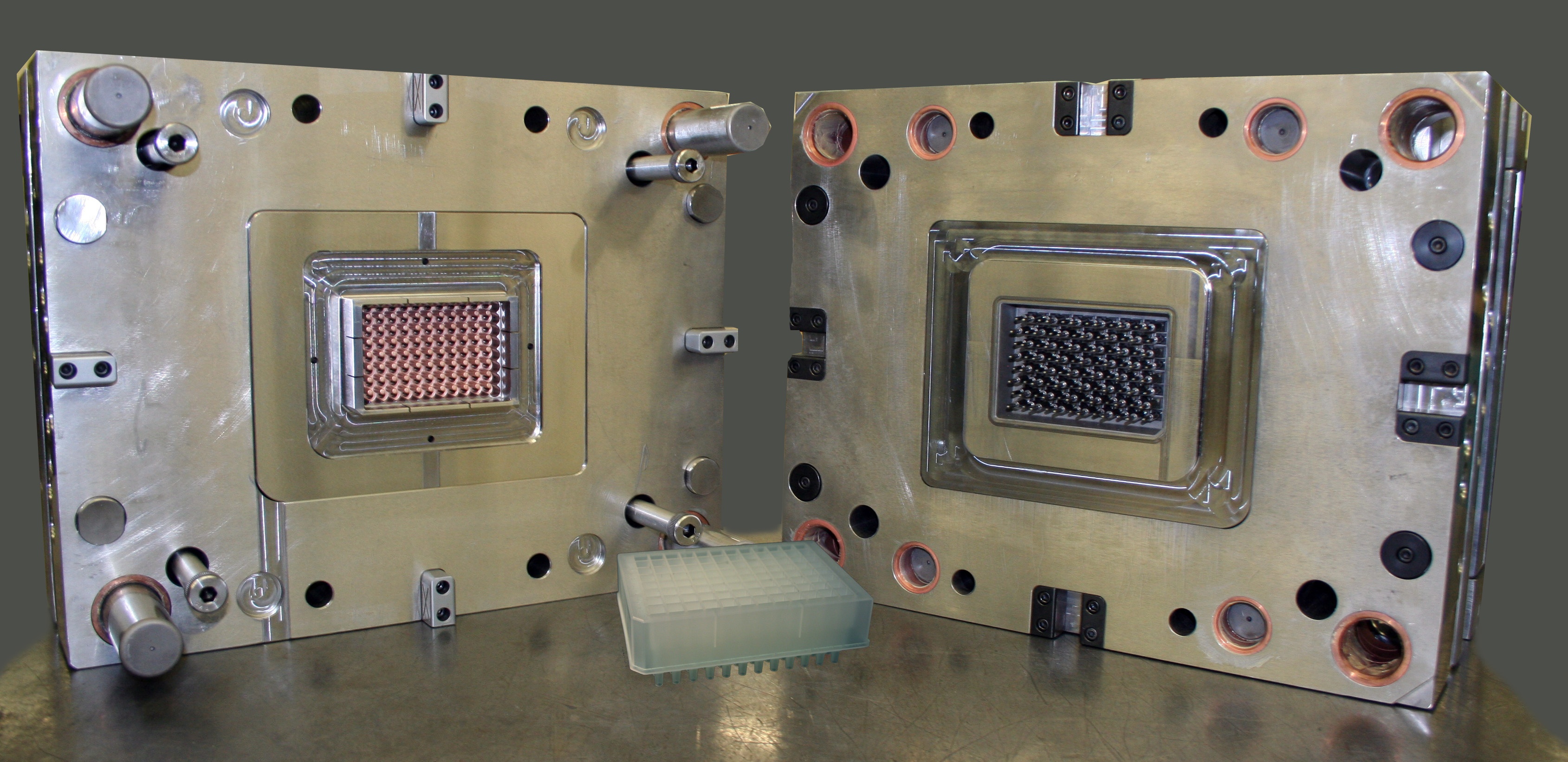

Serving a wide range of injection molding uses, Crescent Industries offers tooling solutions that include mold options ranging from single-cavity to 96-cavity molds. Our team of skilled professionals works with you to identify the factors contributing to a successful project outcome. For more information, contact Crescent Industries today.

Single-Cavity Injection Mold is Part 1 in our injection molding tooling series. To read Part 2 and learn more about multi-cavity molds, click here.

Resources:

https://www.rompagroup.com/news/a-single-or-multi-cavity-mould-which-is-best-for-your-project.aspx

https://www.rptechnologies.co.uk/knowledge-hub-item/Single+Cavity%2C+Multi+Cavity+and+Family+Tools