When it comes to the device sector, outsourced services can range from full service - to carefully targeted functions such as development and production, packaging, or supply chain management. Companies need an injection molding partner that supplements their own competencies in order to bring products to market faster and at a more reliable pace.

In order to do this, the capabilities of the process need to be perfected. There are a number of factors that can make or break an outsourcing alliance. Some of these factors include;

- Competency

- Overall performance

- Speed to market

- Transparency

- Problem solving skills and

- Cultural alignment

The biggest risk in selecting a partner is when the product is not delivered as required, or by the predetermined design specifications. Other problems that can arise include quality standards that do not meet the requirements of the project. Outsourcing partners with relevant experience in the market can help satisfy regulatory standards, documentation and materials for the project.

Successful partnerships need honesty, trust and open communications in order to thrive, succeed and remain long lasting. This is why a shared strategy of where the partnership and business arrangement is heading needs to be understood.

Experience Matters

Selecting an injection molding partner with strong engineering capabilities and technologies will provide options and solutions to help you mitigate the most difficult aspects of part and mold design. An experienced partner will also know how to grow the production process with increasing product volume.

Poor designs create product flaws that will emerge during production. All weak links in design or fabrication processes totally compromise the integrity of the final part - while leading to expensive redesign.

If you have developed a device or component, the design stage is the best time to address how it will be manufactured efficiently. A custom injection molding professional should understand Design for Manufacturing and Assembly (DFMA). This standard means that they can assess and offer the best solution for manufacturing the product for its end use requirements.

Does the injection molder have the technology and skilled personnel to refine the design for manufacturing, production and final assembly or packaging services your project requires? If one manufacturer can provide all of this, it is far more likely the device or component will get to market both quickly, and cost effectively.

Advanced Training and Cutting-Edge Technologies

Tooling engineers utilize technologies to fabricate injection molds that include proper actions, runners, gates, venting and cooling systems to achieve reliable and consistent plastic components.

Journeyman toolmakers require advanced training to calculate the feeds and speeds required to make precise cuts with drills, end mills and other sophisticated CNC equipment. This requires a 4-to-5 year apprenticeship program and significant on-the-job training.

OEMS need a single manufacturing partner that offers all the required manufacturing methods – milling, machining, grinding, molding, assembly, packaging and other post-molding operations.

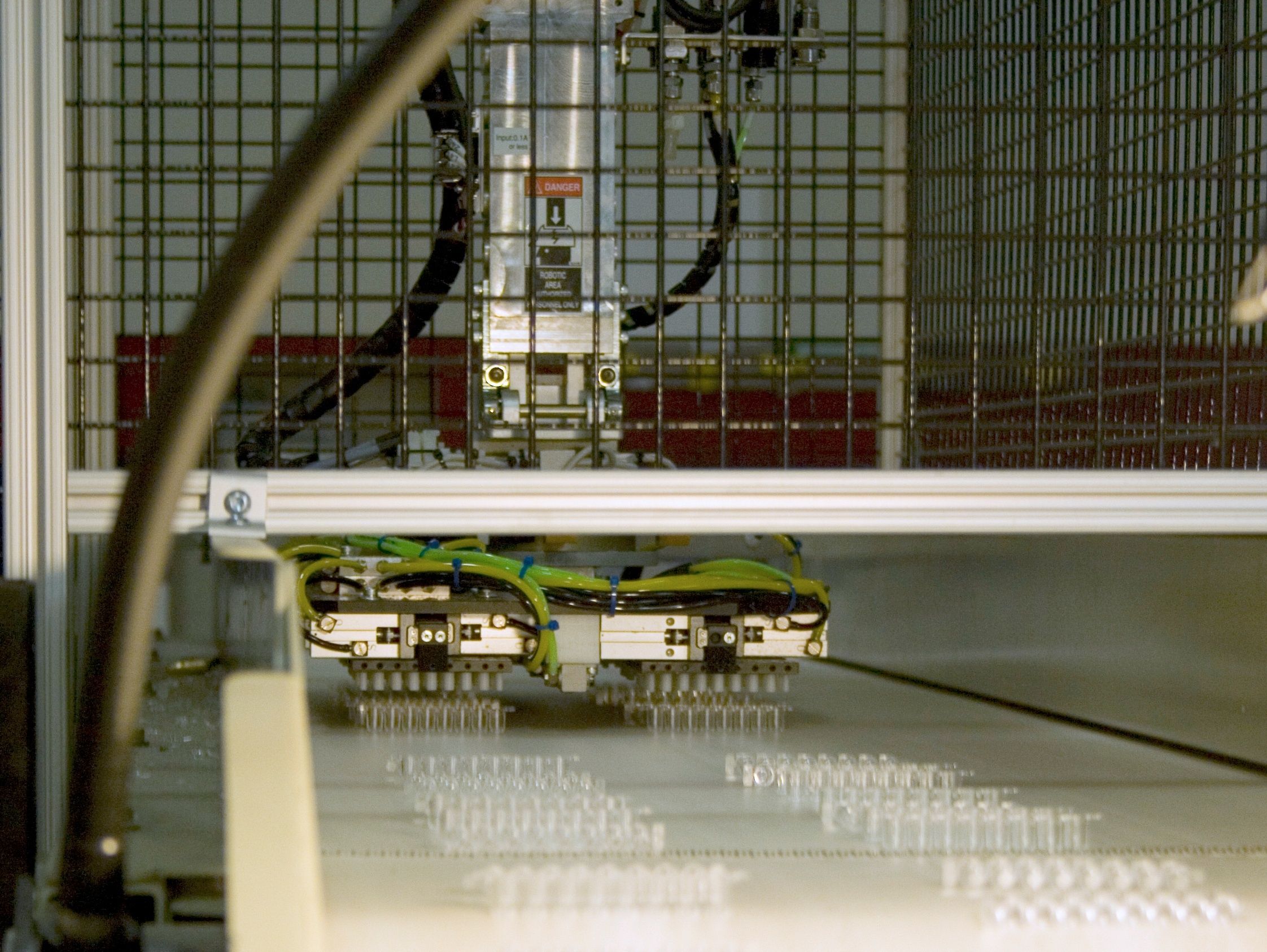

The right partner can refine a design to maximize efficiency during your production runs. Does the molder have efficient manufacturing processes such as robotics or automation? These simplify and streamline production.

Quality Requirements

Choosing an injection molding partner practicing cGMP and has the ability to provide the necessary documentation for ISO certifications and FDA registrations. For example, medical device companies need to ensure that contracts for custom injection molding projects address quality protocols and project requirements.

Does your injection molder provide First Article Inspection reports, real time statistical process control, lean manufacturing and the ability to validate processes to ensure repeatability of their manufacturing and minimize inspection time. Selecting an injection molder that incorporates all your project necessary quality protocols and documentation will avoid unnecessary costs and delays during the manufacturing process and final product launch.

You should select an injection molding partner that offers the right mix of capabilities, expertise, quality and dedication required for your project.

Crescent Industries has operated as an employee-owned custom injection molder and tool builder for plastic components and devices for decades. Partnering with industry experts is the best way to avoid complications, losses and other reputation-critical events.

Source;

MPO article in September 2017 “Nine Critical Considerations When Selecting a Contract Manufacturing Partner” Written by Mike Treleaven, VP, Tegra Medical