(Updated January 2022)

4 Considerations when sourcing your injection molding tools to eliminate risk and achieve the most efficient manufacturing solution.

- Minimize risk by involving suppliers early that provide DFM

- Determine the injection mold classification your project requires

- Decide on the injection mold type for your product.

- Research to choose the right molding partner

Thus, it is critically important to work closely with your injection molding partner from the beginning of your project to manage risk while helping to keep the project on time and budget.

1. Minimize risk by involving the supplier early for DFM

When purchasing and injection mold tooling and molded components, it is essential to involve your supplier early in the process. Mold design engineers will evaluate the part design for manufacturability, running mold fill simulations to ensure the injection mold will have proper actions, runners, gates, venting, and cooling to achieve reliable and repeatable plastic components. Therefore, solving potential problems in the design phase – saves time and money by avoiding costly errors.

Tooling engineers utilize technologies to develop 2D and 3D computer-generated files of injection molds. From these 2D and 3D injection mold models, detailed tool paths are created for specialized CNC machining. Therefore, allowing for an almost unlimited geometry has become good news for producing complex plastic components.

An injection mold toolmaker's job requires advanced training to calculate the feeds and speeds needed to make precise cuts with drills, end mills, and other sophisticated CNC cutting tools - a job requiring a 4 to 5-year apprenticeship program and significant on the job training.

2. Determine the injection mold classification

The Plastics Industry Association is responsible for establishing the customs and practices of the injection mold makers industry. This association classifies injection molds to help eliminate confusion and create uniformity between mold types in the mold quoting system, which increases customer satisfaction. These classifications are Class 101, 102, and 103 and are discussed below in more detail. Understanding the differences between these three classes is essential when sourcing tooling.

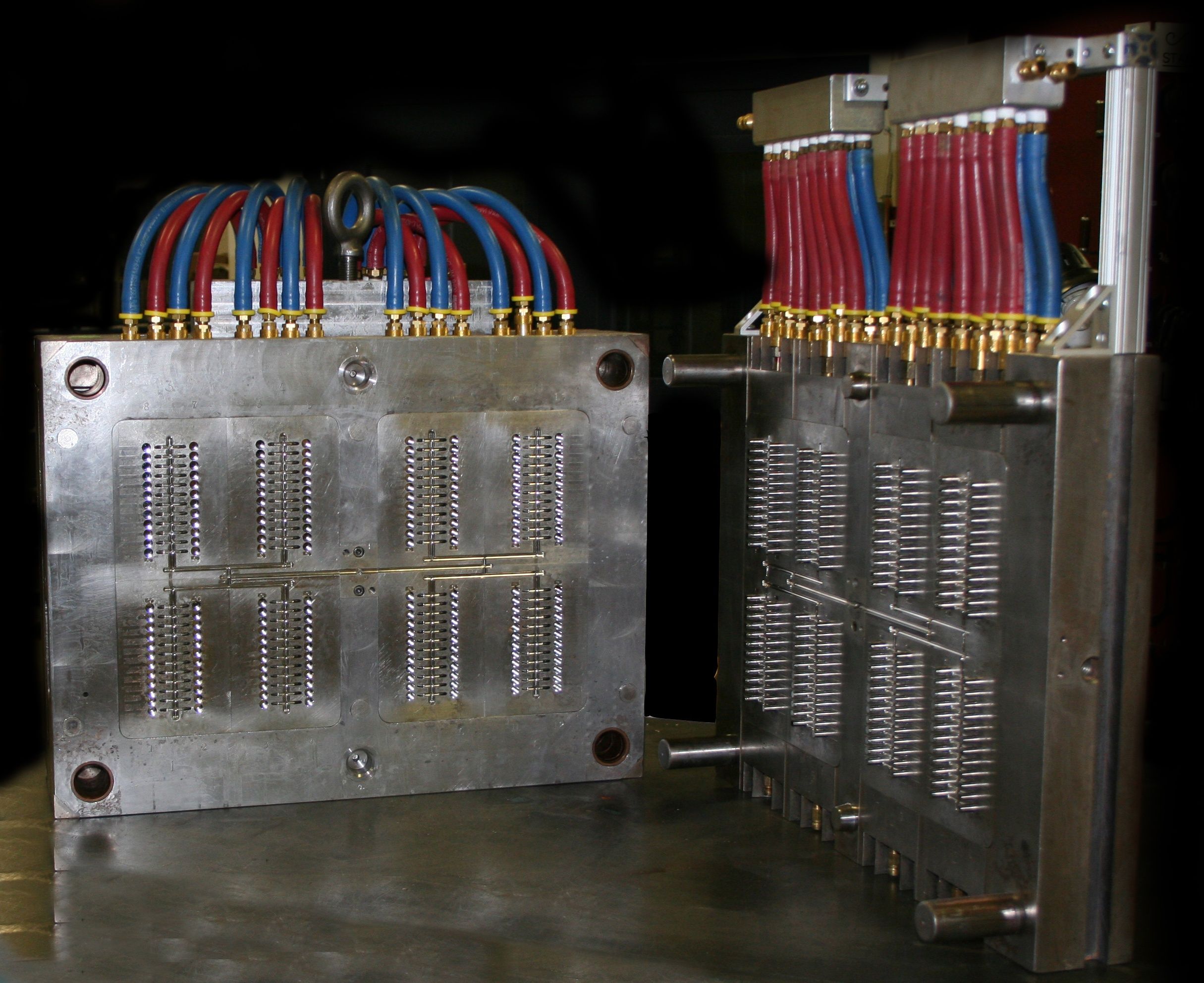

- Class 101– is built for high production runs of over one million or more cycles. These molds are made with the highest quality materials, making them the more expensive ones. The mold base should be a minimum hardness of 280BHN, and molding surfaces (cavities and cores) must be hardened to a minimum of 48 RC. Steels moving against one another should be dissimilar and have a hardness differential of at least 4 Rockwell. Temperature control provisions must be in cavities, cores, and slides wherever possible.

- Class 102– is built for medium to high production runs - not to exceed 1 million cycles. These molds are suitable for abrasive materials. Class 102 molds are fairly high-quality molds as well as being relatively high priced. This mold base should also be a minimum hardness of 280BHN, and molding surfaces (cavities and cores) will be hardened to a minimum of 48 RC. Temperature control provisions should be in cavities, cores, and slides wherever possible.

- Class 103 – is built for medium to low production runs of fewer than 500,000 cycles. The mold base should be a minimum hardness of 165 BHN and cavity and cores of 280BHN or higher.

3. Decide on the injection mold type for your product

The selection of the type of injection mold needed depends entirely on the customer's requirements and product specifications; below is more detail on the various mold types.

- MUD units are standard frameworks for tools, allowing for custom machined inserts for specific components.

- Unscrewing Molds are used when the plastic parts have details like threads or ridges that cannot be quickly injected using the standard knockout methods. These parts are carefully unscrewed from the mold to avoid thread damage. To be cost-effective - these complex molds need to move at high speeds and clear previously molded parts efficiently to begin the next cycle. These molds are suitable for products like medical syringes, vials, caps, and connectors.

- Action Molds have some mechanical action incorporated in the design to enable the molding of complex parts and detailed geometry like a hole, slot, undercut or thread that is not perpendicular to the mold's parting line.

- Hot Runner Molds are typically more expensive to manufacture but save by reducing material waste, cycle time, and labor costs. In addition, these molds can produce more complex components while providing a variety of gating options that improve part quality.

- Three plate Molds have a runner plate between a moving half and a fixed half. These molds have two parting lines and are picked for their gating location flexibility.

- Family Molds are used when all manufactured products are from the same material. These help to eliminate color matching problems because the products are manufactured simultaneously. It is crucial to have proper flow balance, runner shutoffs, and additional cooling circuit control with these molds.

4. Research to find the right molding partner

There are many injection mold tooling partners to choose from, so it is imperative that you research to identify the right one! Below are a few topics to discuss with potential sourcing partners:

- Tooling options and experience: look for a sourcing partner that offers a broad range of tooling options; the right sourcing partner will have extensive experience with various available tooling and material options. Along with experienced, skilled, tool makers.

- Materials: Many different materials can be used in the tooling process depending on the type of tool required and the timing required. The most common materials used for tooling include aluminum, steel, cast iron, carbides, and composites (REN). Certain supply partners specialize in the different material types, so learn the experience of a potential supplier.

- Volume Capabilities: To be cost-effective, make sure the injection mold is built based on the anticipated volume of parts the tooling needs to produce – not significantly more or less. If this rule of thumb is not adhered to, you will develop a tool that is not optimized for your volume needs, and you will likely pay too much for tooling, especially in the case of designing for too high a volume.

- Quality and turnaround time: Finally, you need to understand the timeline for making tools – the fastest toolmaker is not always the right choice because, frequently, quality is sacrificed to make tools quickly. Take your time to find a sourcing partner that produces quality tools in a reasonable timeframe.

At Crescent Industries, we leverage our expertise as injection molders and our advanced technologies and equipment to produce quality injection molds for plastic components. To get your project started right, go to the Guide to Design for Manufacturability In Plastic Injection Molding.