Tooling is a critical aspect of plastic injection molding. It is a big initial investment and needs designed and built properly in order to meet the part specifications during production. Additionally, if the tooling is not correct, modifications are costly and time-consuming! For these reasons, OEMs must carefully select their tooling supplier!

OEMs have the choice between partnering with a single vendor, or multiple vendors, to accomplish their tool building and parts production. When partnering with a single-source provider, such as Crescent, in-house tooling becomes an extension of the production process, providing customers with a complete manufacturing solution, and providing value by minimizing the number of vendors involved and enhancing speed-to-market. Single-source providers streamline manufacturing - resulting in a more cost-efficient process that saves OEMs time and money! Below are the key benefits of a single-source provider with in-house tooling capabilities – and all of these benefits result in cost reductions, and often time savings, for OEMs!

Improved Speed-to-MarketA single-source partner guides OEMs through the design, engineering, product development and production stages smoothly and quickly. In-house tooling capabilities decrease lead times for proto-types as well as production builds – avoiding the shipment of tooling all over the world, thus, increasing the speed-to-market! In addition, in-house tooling allows OEMs and molders to be more nimble and able to easily adapt to design modifications.

Higher QualityWhen OEMs partner with a single-source provider and questions or concerns arise, in-house toolmakers, inspectors, and engineers are able to work in-person and on location to ensure tooling is built to specification and quality issues are avoided. Additionally, it is crucial for OEMs to partner with an injection molder, such as Crescent, who has Design for Manufacturability (DFM) expertise; this means the tool design and manufacturing teams are integrated to allow manufacturability and quality issues to be identified and addressed during the design process instead of after the tool is fabricated – saving OEMs significant product development time and cost!

Enhanced FlexibilityPartnering with a single-source provider also increases flexibility. If there are ideas or changes, OEMs do not need to coordinate between multiple vendors to communicate and try to determine if the change is feasible – they simply inform their single-source provider and the provider works out the rest internally. This simple exchange provides OEMs with greater design and production flexibility.

Lower RiskThe more vendors that are involved in a process, the higher potential for miscommunications and errors – it is that simple. Partnering with a molder that has in-house tooling reduces the number of interfaces and hand-offs, limiting the likelihood for misalignments and mistakes. A single-source partner provides streamlined communication, reducing the risk of issues that cause delays and cost money!

On-site Repairs & MaintenanceRegular inspections, maintenance and cleaning are the best way to protect an OEMs tooling investment and maintain the ability to produce quality parts. Partners with in-house tooling allow for quick, on-site repairs and maintenance – avoiding the transport time to and from an off-site location for these services. Additionally, different types of tooling age at different rates so maintenance needs to be carefully planned. By partnering with a supplier with in-house tooling capabilities, OEMs can leverage their knowledge and experience to ensure the mold maintenance schedule is tailored to the specific needs of each injection mold.

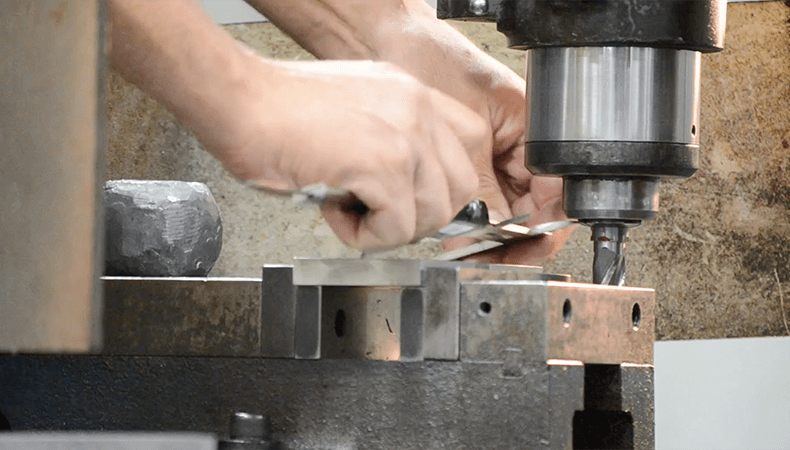

Crescent In-House Tooling CapabilitiesCrescent Industries has been offering in-house tooling solutions for over 70+ years with specialization in building new tooling along with comprehensive maintenance, repairs, and revisions of existing tools to ensure the life of our customers’ tools. Our journeymen mold builders produce injection molds that provide cavity-to-cavity consistency and repeatability by utilizing high-speed CNC mills, die-sink EDM, and wire-sink EDM. We have invested in CMMs which are located in our tooling facility to perform quality inspections during the machining process to verify precision and accuracy. Additionally, we have developed a tool transfer process to ensure a smooth transfer and minimize loss of production time.

We have an in-house full-service toolroom, and we offer single-cavity to 96+ cavity molds. Our tooling capabilities also include:

- MUD (Master Unit Die): the choice when a dedicated or stand-alone mold base is not required. The part, runner, and gate geometry are cut into standardized inserts that fit into the frame.

- Unscrewing Molds: used when there is a requirement for male or female threads on a plastic component.

- Hot Runner System: an assembly of heated components used to inject molten plastic into the cavities of the mold

- Action Molds: Includes mechanical action incorporated into the design when a hole, slot, undercut or thread is needed that is not perpendicular to the parting line

- Two Plate Molds: provides one parting line and the mold splits into two halves; the sprue, runners, gates and cavities are all on the same side

- Three Plate Molds: these molds will have two parting lines and are used because of their flexibility in gating location

Contact us today to learn more about our in-house tooling and complete manufacturing solutions.